CC TAG5 was carefully designed and tested in collaboration with specialists Lyngsoe Systems and Omni-ID, developer of RFID tags for industrial and logistical purposes. Tony Kington, responsible for design and supply of passive UHF RFID tags at Omni-ID, explains the design of the new CC label.

Headlights

Kington: “The whole process starts with the requirements: how will the tag be used, and under what circumstances? Once it was clear what the horticultural industry would need, it was our job to come up with the best design, starting with the selection of the material. We landed on the type of plastic that is used in the automotive industry for headlights. This was a perfect match to what we would need: it is designed to withstand collisions, water and UV radiation, for a period of 10 to 15 years. We could start with the actual design.”

Creating the label

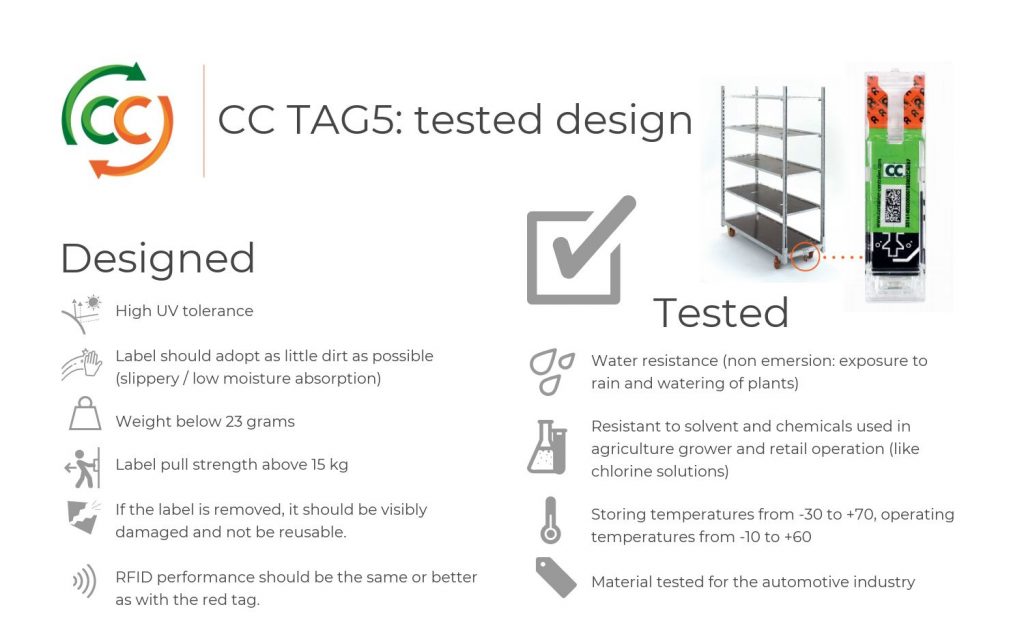

It came to a total of 17 reviews of the design: “The clip in the top part, the way the label bends, the knob in the lower part that comes off if you open it: it was a road of continuous improvement. Also, the placing of the RFID antenna and the way it folds when you attach the label were a real challenge. We had to make the new label a bit longer than the old one, to make this really work. At several stages we tested and benchmarked the new design with the old red tag; it had to perform the same or better on all needed features.“

1-2-3 test

Kington: “We made batches of tags to test on several features in a laboratory setting. What happens if you pull the tag? How much pressure can it take if you crush it? If the tag gets wet, how does this affect the reading performance of the RFID tag? How will it age? This you can simulate by exposing the tag to extreme temperature changes, from -20C to +70C, for up to 700 hours straight. Last but not least, the new label needed to be tamper proof; you should be able to see it when it is taken off and it shouldn’t be possible to re-use it. The new design stood all tests – and performed even significantly better on pulling, crushing, reading when wet and being tamper proof.” Noted should be that this doesn’t mean that the tag is ‘unbreakable’; only that it is expected to perform at least the same as the red tag, so all regular exchange procedures stay in place.

Quality control

Going into actual production was the final step for Omni-ID. Kington: “At this stage we stayed closely involved, to check the quality of production. All 3.5 million tags were tested on RFID performance by running it through a special machine and 182,000 tags were tested on all aspects. This way we made sure that we were delivering the label with all the features that we had promised.” Since January this year all CC Containers are fitted with the CC TAG5, resetting the pool for a fair use of the material.